summary

What Is Waste in Lean Manufacturing Services?

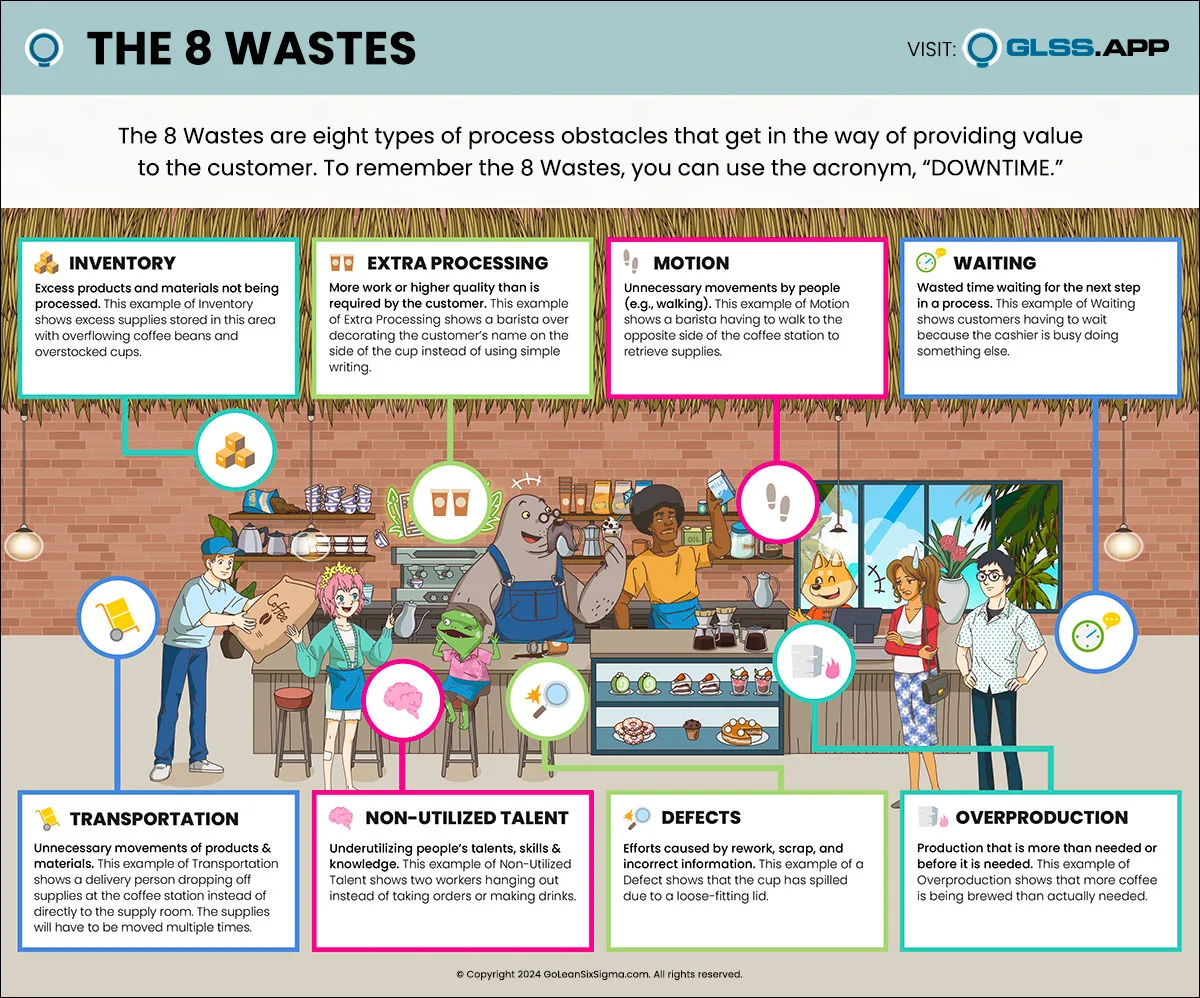

Anyone who’s had a busy day at work can appreciate the value of “downtime.” However, when you start to see through the lens of Continuous Improvement, the term means something entirely different.

It’s a good analogy to remember and a valuable Lean Six Sigma acronym. DOWNTIME refers to the 8 Wastes of Lean manufacturing services that get in the way of process flows.

By understanding what each of the wastes is, you’ll discover new ways to optimize processes, solve problems, and make a greater impact.

Waste is any step or activity in a process that doesn’t contribute value to the final product. This is also known as “Non-Value-Adding.”

Many types of inefficiencies comprise waste. Lean Principles aim to identify and eliminate these Non-Value-Adding elements to optimize Production Processes for the benefit of both the organization and the customer.

A few of these benefits include:

- Providing customer value

- Increasing efficiency

- Reducing cost

When you remove waste, only the steps required to deliver a satisfactory product or service to the customer remain. These steps are called “Value-Adding.”

Reducing waste is part of the Lean Six Sigma (LSS) goal of Continuous Improvement.

Another way to look at it is to consider the old adage: “Work smarter, not harder.”

But instead of just well-intentioned speculation, LSS provides a methodology with specific steps toward “working smarter.”

By following LSS practices, you determine the Non-Value-Adding processes by comparing them to the 8 Wastes. Addressing and eliminating these wastes is fundamental to Lean Principles and contributes to a more streamlined, efficient, and “smarter” manufacturing process.

How Did Lean Waste Originate?

Modern Lean practices were developed in the 1980s through the Toyota Production System in Japan as a business philosophy to maximize efficiency. Toyota’s system was built on dual foundations of “Just-In-Time Inventory Management” and “Automated Quality Control.”

But traditional Lean practices go back in history even further, all the way to production mindsets formed in Venice, Italy, in the 1450s to standardize galley ship manufacturing.

Since then, the philosophy has been fine-tuned by forward-thinkers of production such as Eli Whitney, Henry Ford, and Toyota’s Taiichi Ohno, all following the same belief: When excess is removed from a process, it is reduced, or “becomes Lean.”

Ohno is credited as further defining the actual concept of waste (“Muda” in Japanese) into formalized categories in Lean Manufacturing (originally seven instead of eight). Organizations have adopted this approach worldwide to improve efficiency, reduce costs, and enhance overall productivity.

What Are the 8 Wastes?

The 8 Wastes is a really interesting way of thinking about waste and exploring the problems in a system or process. It’s not just about cost-cutting, it’s about making the most impact with the resources you have, including the talent, materials, and time that go into a product or service.

Using the acronym DOWNTIME is a great way to remember what the wastes are:

- Defects

- Overproduction

- Waiting

- Non-Utilized Talent

- Transportation

- Inventory

- Motion

- Extra Processing

Identifying and addressing these wastes is fundamental to Lean Principles and contributes to streamlined and efficient processes.

Here’s a more detailed explanation of each of the 8 Wastes.

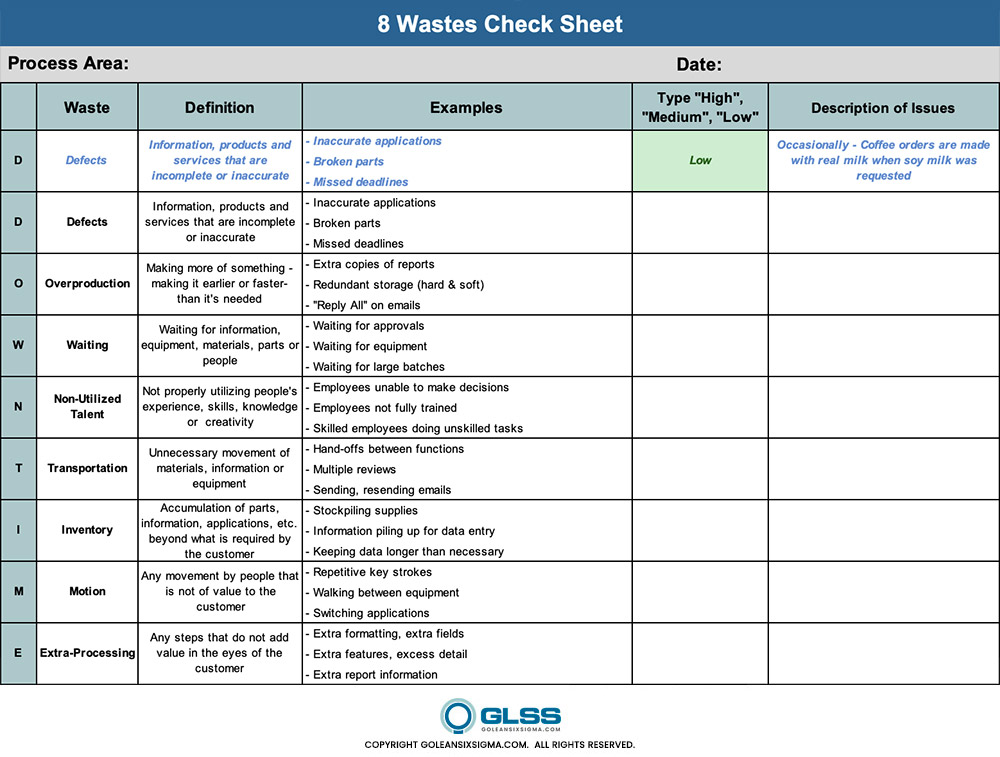

Defects

Defects are products or services that have flaws or don’t meet the specified quality standard in some way. A defect results in either product rejection or rework, which requires resources to correct.

Considering the cost of additional resources, including time, labor, material, etc., you can imagine the quick accumulation of costs. And a product rejection may be even worse – it can mean a full-loss.

As customers, we’ve all experienced a product defect. Besides the disappointment and inconvenience, there’s also a negative association with the product.

Even when the defect is rare, it’s human nature to remember “the time an item didn’t work,” damaging the company’s reputation.

By addressing defects promptly, organizations minimize waste, optimize resources, and enhance the reliability and reputation of their products in the marketplace.

Overproduction

Overproduction is when you produce more goods or output than you can sell. This type of waste leads to the accumulation of excess inventory, tying up finances and storage space.

Think of it like this: you produce three extra batches of raincoats based on inaccurate forecasts. Now you’ve spent thousands of dollars on a product no one wants or needs.

Besides the costs, overproduction also risks its “extra” products becoming obsolete or degrading in quality over time.

Back to the raincoats – now you have dozens of extra coats taking up valuable space in your warehouse, slowly going out of style.

Additionally, creating products in large quantities before verifying the quality of the initial batches can lead to unnecessary waste, especially if defects are discovered later.

So it finally rains…and you find out, too late, that your raincoats aren’t waterproof!

By minimizing overproduction from both product manufacturing and service, organizations can be more responsive to customers’ needs – and achieve a more sustainable production system.

Waiting

Waiting refers to any idle time or delay in the production process where work isn’t actively being done. In terms of manufacturing, this particular waste occurs when waiting for the previous step in a process to finish, like a bottleneck.

However, you can find waiting in various forms, like standing in line, equipment breakdowns, material shortages, or inefficient scheduling. Lean Principles emphasize the importance of Continuous Flow and aim to eliminate waiting to enhance overall Operational Efficiency.

Addressing the waste of waiting involves streamlining processes, optimizing production schedules, and ensuring a smooth and uninterrupted workflow. All with the goal of reducing lead times, improving productivity, and responding more promptly to customers.

Non-Utilized Talent

Non-utilized talent is the insufficient use of employees’ skills, creativity, or potential contributions within an organization.

This occurs when employees aren’t effectively engaged or their talents aren’t applied to add value to the production process. In a Lean environment, recognizing and tapping into your workforce’s diverse skills and ideas is essential for Continuous Improvement and innovation.

Fostering a culture that encourages employee involvement, empowerment, and collaboration is key to addressing non-utilized talent waste.

By actively engaging employees in problem-solving and decision-making, organizations can unlock the full potential of their workforce. This leads to improved efficiency, higher job satisfaction, and a more dynamic and responsive manufacturing environment.

Transportation

Transportation refers to the unnecessary movement of materials, items, or information within the production process.

Think of a company that requires a lot of paper. They order pallets of it. These pallets are loaded onto a truck, driven to the company, unloaded at the outside bay, moved to a processing area, and finally moved to a storage area. That’s a lot of transportation!

A streamlined process would take paper directly from the truck to the storage area, minimizing the number of times the pallet is handled.

Other examples of Transportation waste include moving electronic data from one system to another or employees having to travel to different locations for meetings.

The waste from excessive movement of materials can lead to increased handling costs, longer lead times, and a higher risk of damage.

By reducing unnecessary transportation, organizations can enhance Operational Efficiency, streamline production, and lower costs associated with handling and logistics.

Inventory

Inventory is the accumulation of excess materials, products, information, or work-in-progress beyond what is immediately necessary or otherwise idle.

This type of waste consumes an organization’s finances, occupies storage space, and increases the risk of obsolescence.

Imagine a coffee shop that ordered extra lids, stirrers, and packets of sugar – just to have on hand for when they need them in the future. These items aren’t currently needed and will create additional costs and take up space.

One of the biggest tools to combat this is the principle of Lean’s Just-In-Time (JIT) production methods, where materials are procured and used precisely when needed.

Reducing inventory levels not only frees up capital and leads toward Continuous Improvement, but also helps identify and address other inefficiencies in the production process, like Transportation and Overproduction.

Extra Processing

Motion refers to people, information, or equipment and their unnecessary movement due to workspace layout, searching for misplaced items, etc. Examples of this waste include excessive walking, reaching, or handling of materials that could be streamlined or eliminated.

If a barista needed paper cups and plastic lids to prepare a to-go drink, keeping each of those supplies in different areas creates waste – needless motion, moving from one area of the counter to the other.

Organizations can improve worker productivity, reduce the risk of injuries, and create a more efficient and sustainable manufacturing system by designing work areas that minimize unnecessary motions.

Motion

Extra Processing (also called Overprocessing) refers to any activity that’s not necessary to produce a functioning product or service.

Essentially, this waste includes unnecessary or redundant steps in a process that consume resources without contributing to quality or functionality.

Examples of this waste could be too many inspections or testing that goes beyond what’s necessary to ensure product quality.

Besides overproduction from a manufacturing stance, you can also find this waste in services – like government or medical forms that ask for more information than necessary, leading to additional time for completion and data processing.

To eliminate this waste, you need to critically evaluate each step in the production process to ensure that every action adds value and contributes to the quality of the final product.

How to Identify Waste

Identifying waste involves a systematic analysis of your entire production process so you can pinpoint what falls into the Non-Value-Adding category and adjust. You can use several methods to do this, like:

- Process Maps are step-by-step diagrams that show the work needed to be done to complete a process.

- Gemba/Process Walks allow managers and team members to observe the actual work to identify inefficiencies.

- Value Stream Mapping(VSM) visually represents the entire production process to highlight areas of waste and opportunities for improvement.

- A Value-Add Analysis examines cycle times, lead times, and defect rates, and can also reveal patterns of waste.

- Engaging employees in continuous improvement initiatives and encouraging them to voice concerns or suggestions can be invaluable in identifying areas of non-value-adding activities.

You can start learning how to create real impact while completing real projects that reduce waste and drive business results with our free training!

Have You Heard About TIMWOODS?

At GLSS, we use DOWNTIME, but there’s another acronym you may come across with the same purpose — TIMWOODS.

- Transport

- Inventory

- Motion

- Waiting

- Overproduction

- Over-processing

- Defects

- Skills utilization

You can use whichever acronym best helps you remember the 8 wastes. Understanding them and how they apply to your processes is the most important part.

Organizations can identify and address waste by adopting a natural and collaborative approach, leading to a more streamlined, efficient, and customer-focused manufacturing process and avoiding DOWNTIME.

Get a free trial of GLSS training for you or your team to start eliminating waste in your workflow today!

Or automate your Lean Six Sigma projects with AI using Kure.

Read more

Read more